Special effects printing

Protective coatings & lamination for print materials

Coatings & Lamination

extend the lifespan of prints,

maintain their appearance,

and can even contribute to

environmental sustainability.

Protective Coatings

Vs. Lamination

Protective Coatings

Protective coatings are essential in preserving the integrity and appearance of printed materials. They serve as a barrier against environmental factors, handling, and wear, ensuring that your prints maintain their quality over time. By selecting the appropriate coating, you can enhance the visual appeal and longevity of your printed products.

lamination services

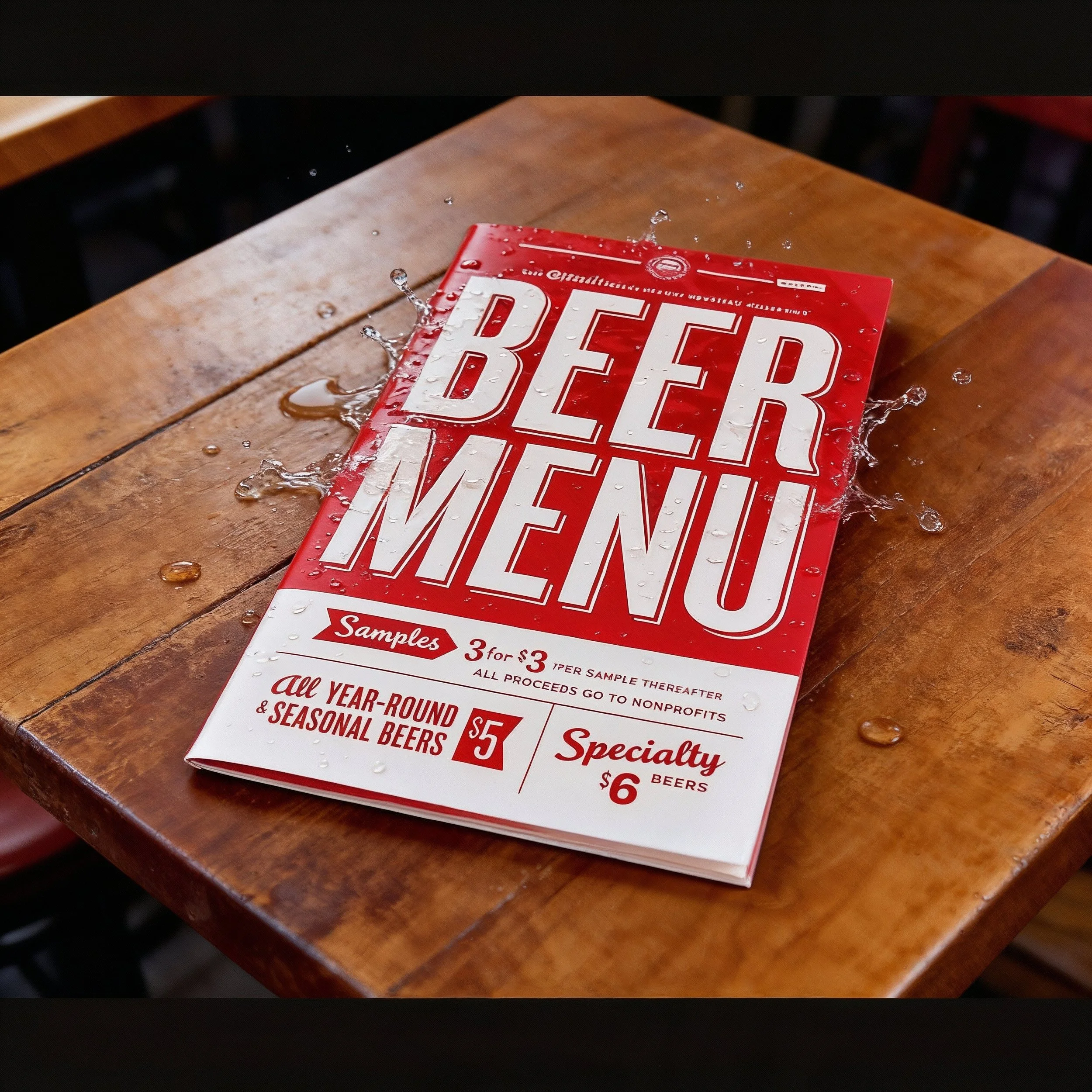

Lamination involves applying a thin film to both sides of printed materials, making them more durable, rigid, and resistant to moisture, smudges, and tears, while also brightening colors and adding a professional finish like gloss or matte. This process not only safeguards against physical damage but also adds a tactile dimension to your prints and extends it’s lifespan

Frequently asked questions

-

Lamination on print materials is the process of bonding a thin, clear plastic film to paper or cardstock to protect it from damage and enhance its appearance, making it more durable, rigid, and resistant to moisture, smudges, and tears, while also brightening colors and adding a professional finish like gloss or matte.

-

Protection: Guards against spills, fingerprints, dirt, moisture, tears, and UV fading.

Durability: Adds significant strength and rigidity, ideal for frequently handled items.

Enhanced Appearance: Makes colors more vibrant and provides a polished look, with options like glossy, matte, or textured finishes.

Professionalism: Elevates perceived quality and adds value to marketing materials.

Easy to Clean: Laminated surfaces can often be wiped clean.

-

Menus: Withstand spills and heavy use.

Book Covers & Brochures: Add longevity and a premium feel.

Business Cards & ID Cards: Increase durability for frequent handling.

Posters & Signage: Protect against wear in outdoor, public or damp environments.

Maps & Educational Materials: Essential for items that are handled often.

Packaging: Used commonly in many Industries such as medical, marketing, personal care, cosmetics, food and beverage, and more.

-

Coatings on print materials are protective and decorative layers (like gloss, matte, soft-touch) applied after printing to enhance durability, resist scratches/moisture, and improve appearance with vibrant colors or sophisticated textures, using finishes like water-based aqueous or UV-cured coatings, or thicker laminates, making prints more professional and long-lasting for items like business cards, brochures, and packaging.

-

Varnish: A basic, cost-effective liquid coating, available in gloss, satin, or dull finishes, offering subtle sheen and some protection.

Aqueous Coating: A fast-drying, water-based coating that provides good resistance to smudges and fingerprints, with glossy or matte options.

UV Coating (Ultraviolet): Cured by UV light, offering a very high-gloss finish, superior durability, and making colors pop.

Soft-Touch Coating: A matte finish that provides a luxurious, velvety feel, adding a premium tactile experience.

Lamination: Applying a thin plastic film (like polypropylene or polyester) for maximum durability and a premium, durable feel, often used for outdoor or high-wear items.

-

Brochures, flyers, and catalogs

Business cards and postcards

Book covers and packaging

Cosmetic Packaging

Influencer Boxes and Kits

Luxury Boxes and Packaging

Retail signage

How to Elevate your Print,

Packaging & Brand Impact

Enhance your prints with specialty coatings & laminations. Soft touch, spot UV, gloss, matte, and durable finishes that elevate brand impact and protection.

Enhance Your Brand with

Special Effects Printing

By incorporating special effects in printing, you can elevate your designs to new heights and make them truly unforgettable.